News

- Industry news

Industry news

Plastic products - plastic hose

Types of hoses

1. Rubber hose

Rubber hose is a commonly used hose for conveying water, oil, gas and chemical liquids, which is composed of an inner rubber layer, a strengthening layer and an outer rubber layer. Rubber hose has wear resistance, high temperature resistance, cold resistance, oil corrosion resistance and other characteristics, is a common material in many industries.

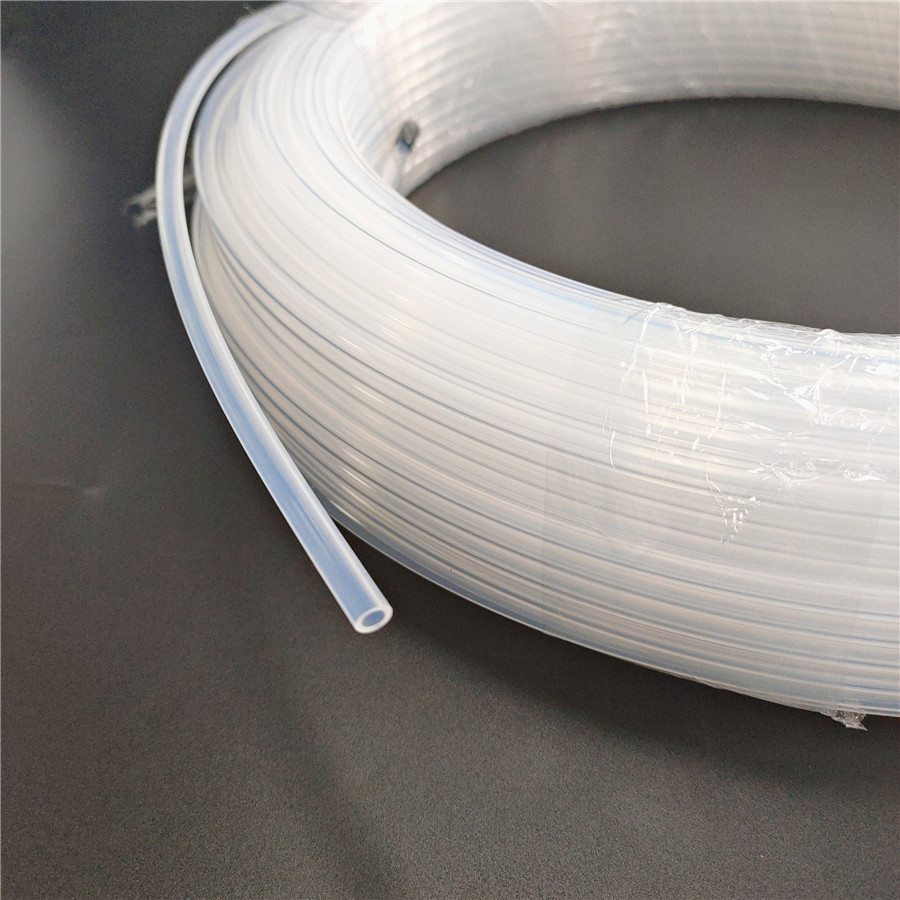

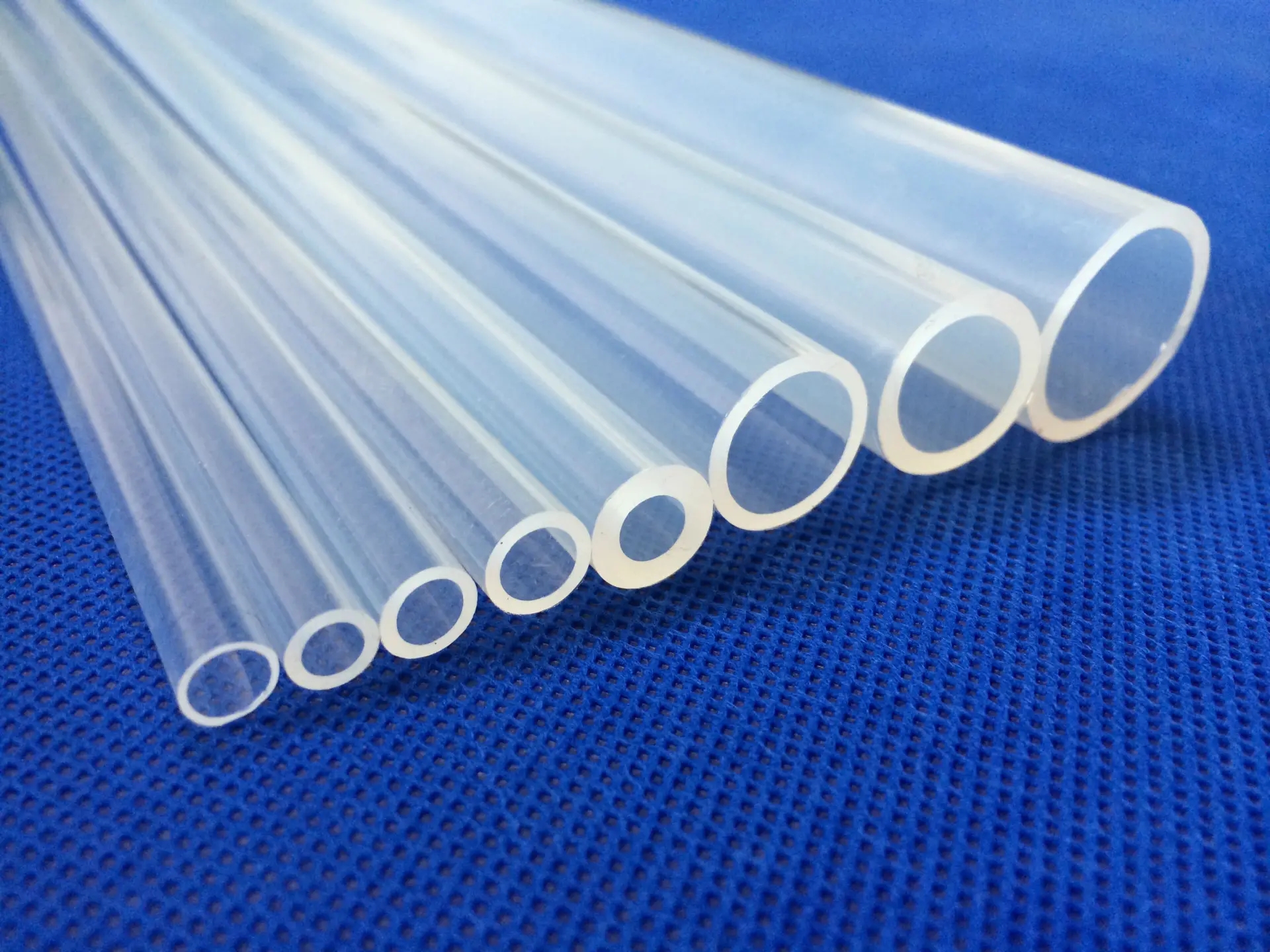

2. Plastic hose

Plastic hose refers to a hose made of thermoplastic, usually used to transport drinking water, gases, chemicals, etc., which is characterized by cheap price, light weight, high transparency, good insulation.

3. Metal hose

Metal hose is a hose made of corrugated pipe technology, which is suitable for high temperature, high pressure, corrosion resistance and other occasions, such as petrochemical, manufacturing, steel smelting and other fields.

4. Polyurethane hose

Polyurethane hose is a new type of hose material, high temperature resistance, oil corrosion resistance, anti-static, high compressive strength, widely used in automotive, electronics, machinery, medical and other fields.

5. Silicone hose

Silicone hose refers to silicone rubber as raw materials, processed into a flexible conveying pipe, with superior high temperature resistance, corrosion resistance, aging resistance, oxidation resistance and conductive properties, widely used in aerospace, electronic instruments, medical and other fields.

What is plastic hose?

Plastic hose material is generally plastic resin as raw material, adding stabilizer, lubricant, etc., by plastic method in the pipe making machine by extrusion processing. Because it has the characteristics of light weight, corrosion resistance, beautiful appearance, no bad odor, easy processing, convenient construction, etc., it has been more and more widely used in construction engineering. Mainly used for building water supply system distribution pipe, drainage, exhaust and sewage sanitation pipe, underground drainage pipe system, rain pipe and wire installation matching with the threading pipe and so on.

Plastic hose features

1, flexible between the pitch.

2, has good flexibility, no blocking and stiffness.

3, light weight, good caliber consistency.

4, flexibility, repeated bending, flexibility is good.

5, corrosion resistance, high temperature resistance.

6, anti-rat bite, good wear resistance, prevent internal wires from being worn.

7, bending resistance, tensile performance, strong resistance to side pressure.

8, soft and smooth, easy to thread installation positioning

9, the design is novel, unique, and reasonable structure, breaking through the traditional plate structure of ordinary pipes,

10, with very good compressive and impact strength, and in use also has good flexibility function, can be twisted and bent, etc., very convenient, sensitive, with insulation.

Plastic hose commonly used material

1, PVC material

PVC plastic pipe is the most common kind of plastic pipe material. It has good chemical resistance and high temperature resistance, and can be used to transport low concentrations of acids, alkalis, salts and other chemicals. Widely used in construction, industry, agriculture, water supply and drainage and other fields.

2, PE material

PE material plastic pipe is also very common, is a non-toxic, tasteless, odorless thermoplastic pipe material. PE pipes have the characteristics of corrosion resistance, anti-aging and good flexibility, and are usually used in water supply, natural gas and heating pipelines.

3. PPR material

PPR plastic pipe is a new type of plastic pipe material that is relatively popular at present. It has the characteristics of high temperature, high pressure, corrosion resistance, safety and non-toxic, and is usually used in heating, water supply and other fields.

4, PVC-C material

PVC-C plastic pipe is a common plastic pipe material. It has excellent high temperature resistance and can withstand higher temperatures and pressures after high temperature chemical treatment, and is usually used in the transportation of high temperature fluids and chemical raw materials.

5, ABS material

ABS plastic pipes are also very commonly used in some specific areas. For example, it can be used to make sewage pipes, interfaces and exhaust pipes. ABS plastic pipe has the characteristics of good flexibility, impact resistance, flame retardant, heat resistance, etc., is a very excellent engineering plastic.

6, FEP material

FEP plastic pipe is one of the most common plastic pipe materials. It has good chemical resistance and high temperature resistance, good processing performance and excellent chemical stability.

Steps to use plastic hose

1, need to check the plastic hose first. Check the appearance and bend of the hose before use to make sure there are no cuts or wear and no visible cracks.

2, then connect the plastic hose well, ensure that the connection is tight, and use the correct connector and seal.

3, choose the appropriate plastic hose. Select the plastic hose suitable for the use scenario, according to the required working pressure and temperature range to determine.

4, do not stack the plastic hose on the pile or exposed to the sun. Before storage, make sure the hose is clean, dry and stored in a dry, warm place.

5, when using plastic hoses, pay attention to the correct handling, avoid twisting or stretching the hose, and use the correct tools and methods when installing and removing. If the hose is damaged, it should be replaced in time.

6, regularly check whether the plastic hose is damaged, deformed or aging. If the problem is found, it should be replaced in time.

Guangzhou?Best?Rubber?And?Plastic?Co.,Ltd.

Tel:(020)31523725, 37523936, 31523097

Tel:(020)31523725, 37523936, 31523097 Fax:(020)37403270, 37403280

Fax:(020)37403270, 37403280 Email: sales@gz-best.com/export@gz-best.com

Email: sales@gz-best.com/export@gz-best.com Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province

Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province Add:25-27 Yanling Road, Guangzhou

Add:25-27 Yanling Road, Guangzhou

Follow WeChat

COPYRIGHT Guangzhou Best Rubber And Plastic Co.,Ltd. 粵ICP備05087523號(hào)