News

- Industry news

Industry news

Popular science knowledge: plastic hot forming

What plastic thermoforming?

Hot molding processing is to clip the sheet on the frame and heat to the softening state, under the action of external force, make it close to the mold surface, cooling and finalize the product, this method is also used for rubber processing, compared with injection molding, has high production efficiency, the use of plastics mainly polystyrene, polyvinyl chloride, polyolefin and so on. Thermoforming products are characterized by thin wall, large surface area and half shell structure. The types of products include cups, dishes and other daily utensils, medical utensils, electronic instrument accessories, radio and TV casings, billboards, bathtubs, toys, helmets, packaging utensils, etc. There are also auto parts, construction components, chemical equipment, radomes and aircraft hoods.

Plastic thermoforming process

1. Vacuum forming

There are dozens of hot forming methods, vacuum forming is one of its representatives.

The sheet softened by heat is pressed against the die surface by vacuum. This method is the most simple, but the vacuum caused by the pressure difference is not big, only used for simple appearance products.

2. Pneumatic thermoforming

Compressed air or steam pressure is used to force the sheet softened by heat to be pressed against the surface of the die. Because the pressure difference is larger than that of vacuum forming, it can manufacture the products with more complex shape.

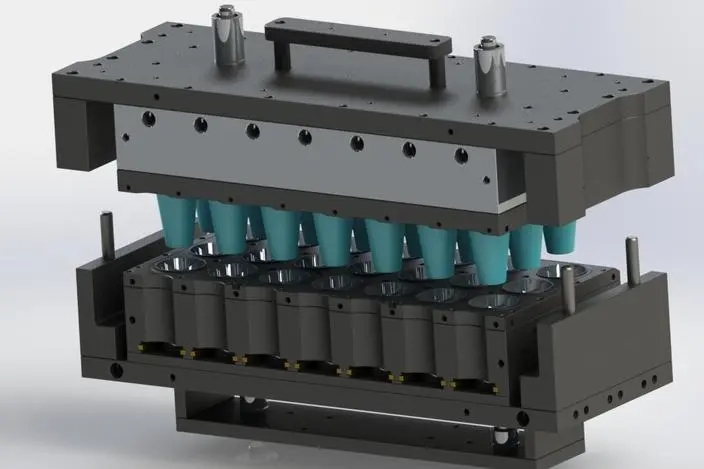

3. Hot forming of die

The sheet softened by heat is placed between the paired Yin and Yang dies and formed by mechanical pressure. The molding pressure of this method is larger, and it can be used to manufacture complex products, but the mold cost is higher.

4. Plunger compression molding

By prestretching the heated sheet with a plunger or a positive die, and then forming it with vacuum or air pressure, the product with large depth and uniform wall thickness distribution can be made.

5. Solid phase molding

The sheet is heated to a temperature that does not exceed the melting point of the resin so that the material remains in a solid state for molding. Used for ABS resin, polypropylene, high molecular weight high density polyethylene. The rigidity and strength of the parts are higher than that of the general thermoforming products.

6. Double sheet hot forming

Two pieces of laminated together, the middle of the air, can be made of large hollow parts.

Advantages of plastic thermoforming

1. Good dimensional stability;

2. High mechanical properties;

3. No parting line, high productivity, good quality, low cost

There are no parting lines, which makes it unique and better than many other plastic manufacturing processes and usually requires minimal work once the process is complete

4. Wide range of applications using a variety of materials

5. Enhanced mechanical properties High temperature thermoplastics exhibit high levels of toughness, strength, stiffness, fatigue resistance and ductility.

6. Recyclable

Because of their ability to form many times, high-temperature thermoplastics can be easily recycled and still have the same dimensional integrity and strength as before.

Attention should be paid to plastic hot forming

1. High temperature, high pressure and high speed injection should be used.

2. The crystalline material should be adjusted according to the requirements, and should prevent the accumulation of resin and glass fiber, glass fiber exposure and local burns.

3. Pressure preservation and feeding should be sufficient.

4. Cooling of plastic parts should be uniform.

5. The change of material temperature and mold temperature has a great influence on the shrinkage of plastic parts. The high temperature has a great shrinkage, and the increase of pressure retaining and injection pressure can make the shrinkage smaller but the influence is small.

6. Due to good rigidity of reinforcement material and high thermal deformation temperature, it can be removed at a higher temperature, but pay attention to uniform cooling after removal.

7. Appropriate release agent should be selected.

Guangzhou?Best?Rubber?And?Plastic?Co.,Ltd.

Tel:(020)31523725, 37523936, 31523097

Tel:(020)31523725, 37523936, 31523097 Fax:(020)37403270, 37403280

Fax:(020)37403270, 37403280 Email: sales@gz-best.com/export@gz-best.com

Email: sales@gz-best.com/export@gz-best.com Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province

Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province Add:25-27 Yanling Road, Guangzhou

Add:25-27 Yanling Road, Guangzhou

Follow WeChat

COPYRIGHT Guangzhou Best Rubber And Plastic Co.,Ltd. 粵ICP備05087523號(hào)